Description

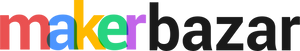

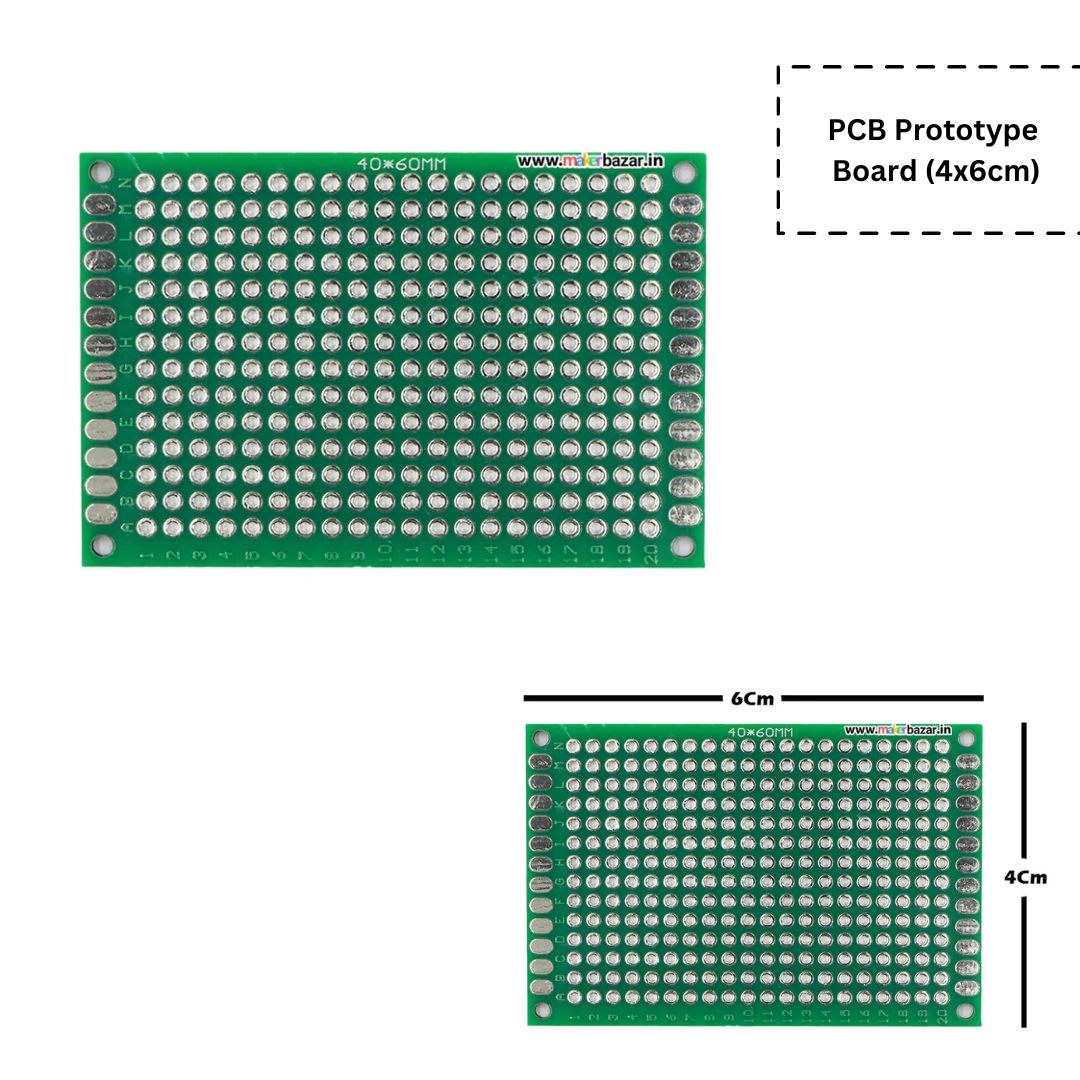

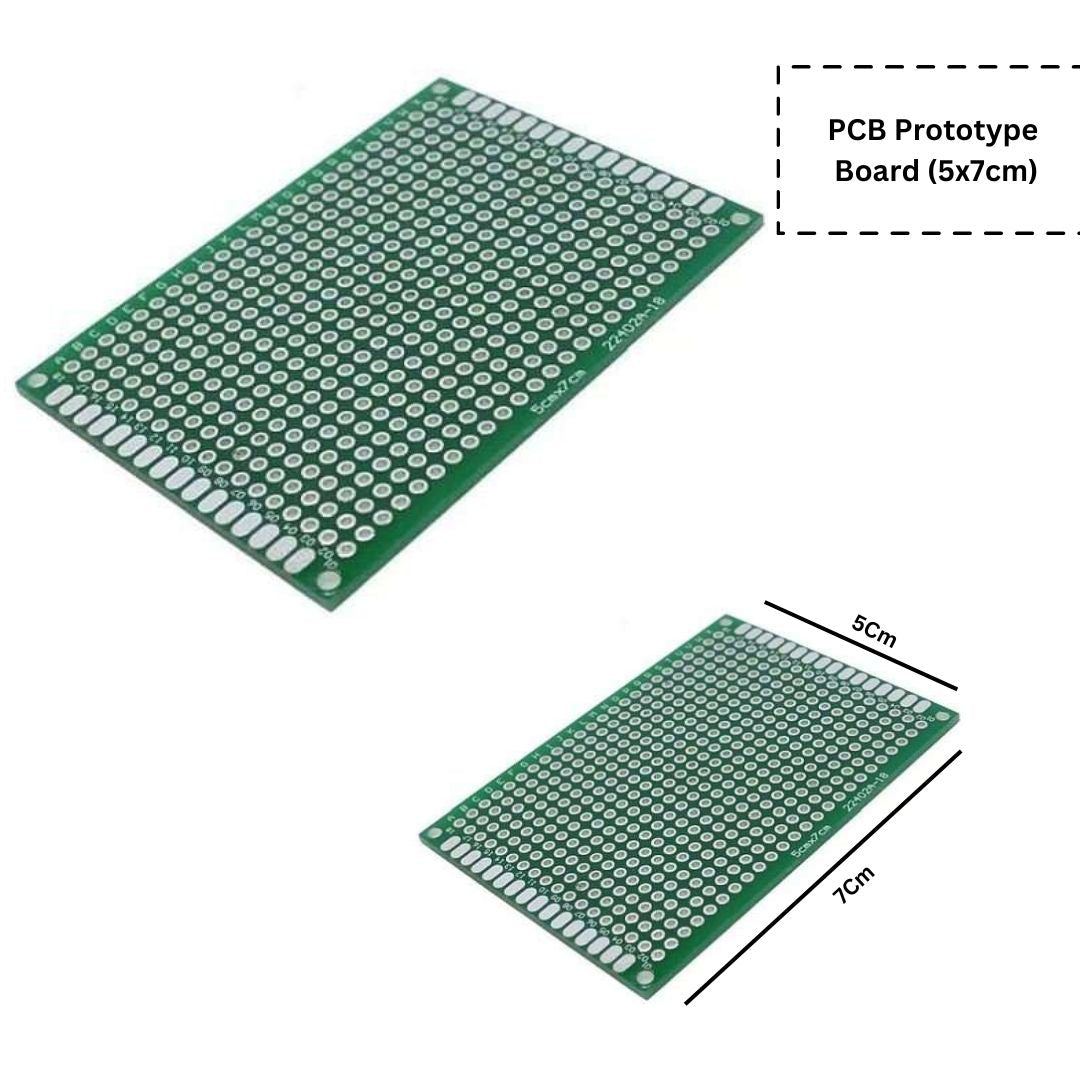

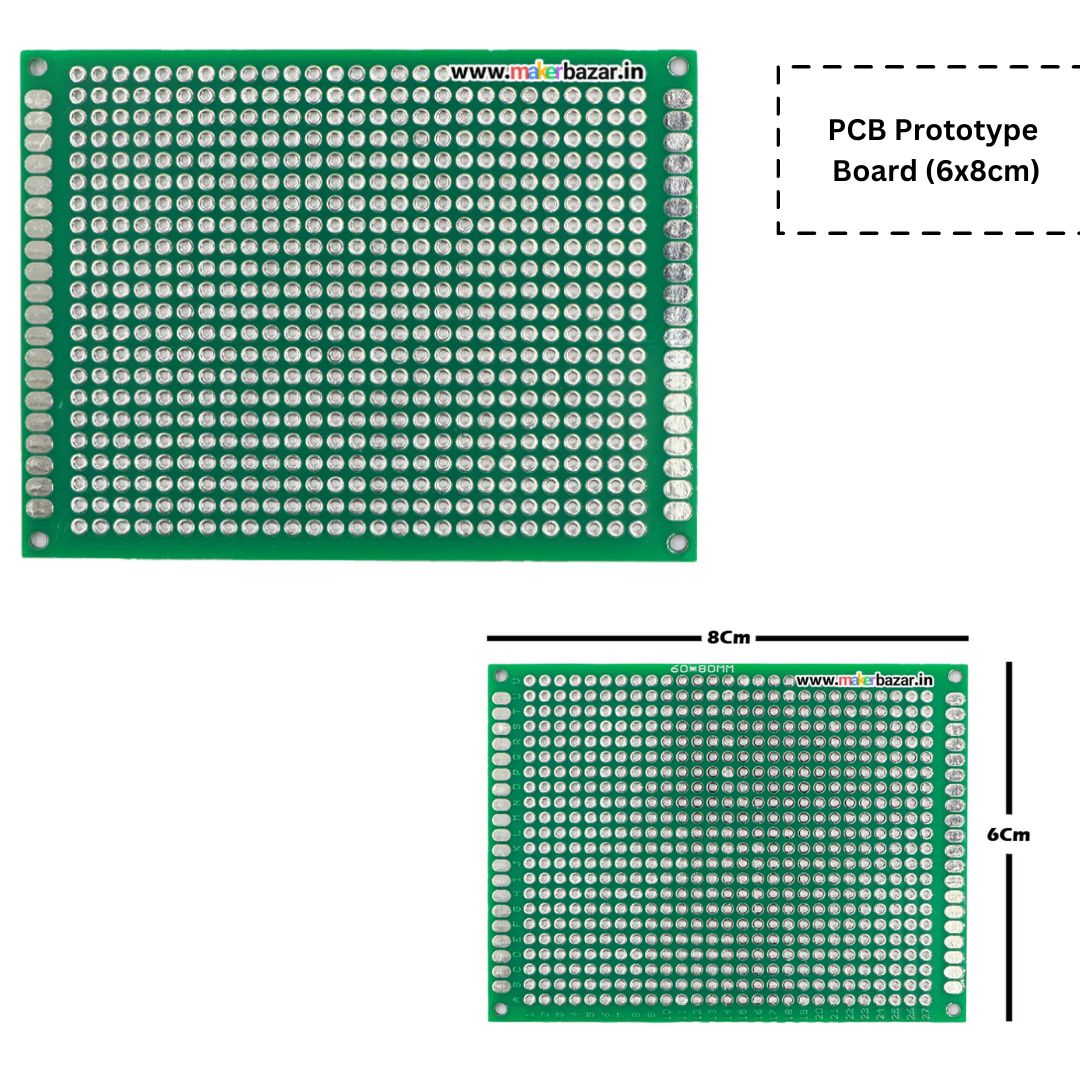

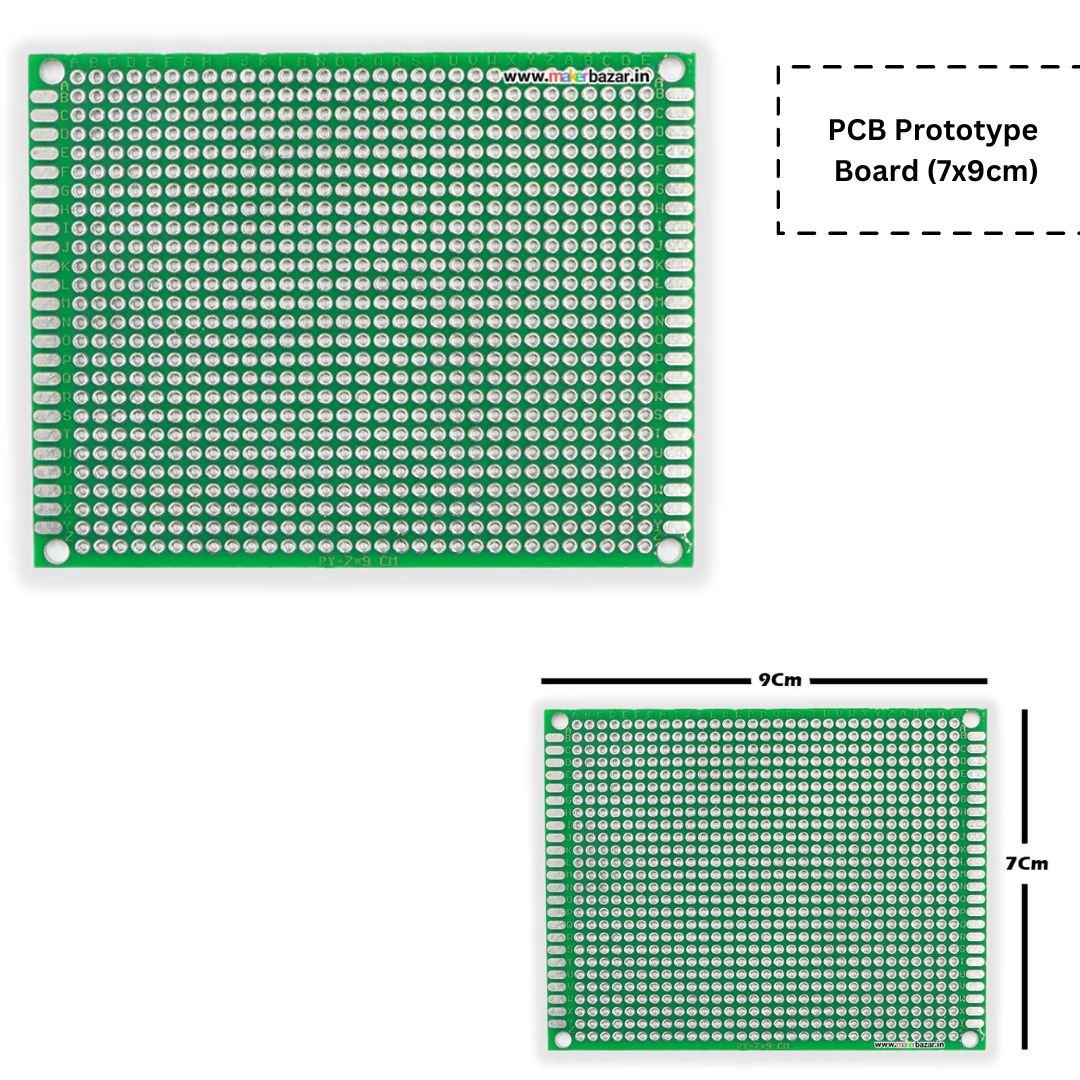

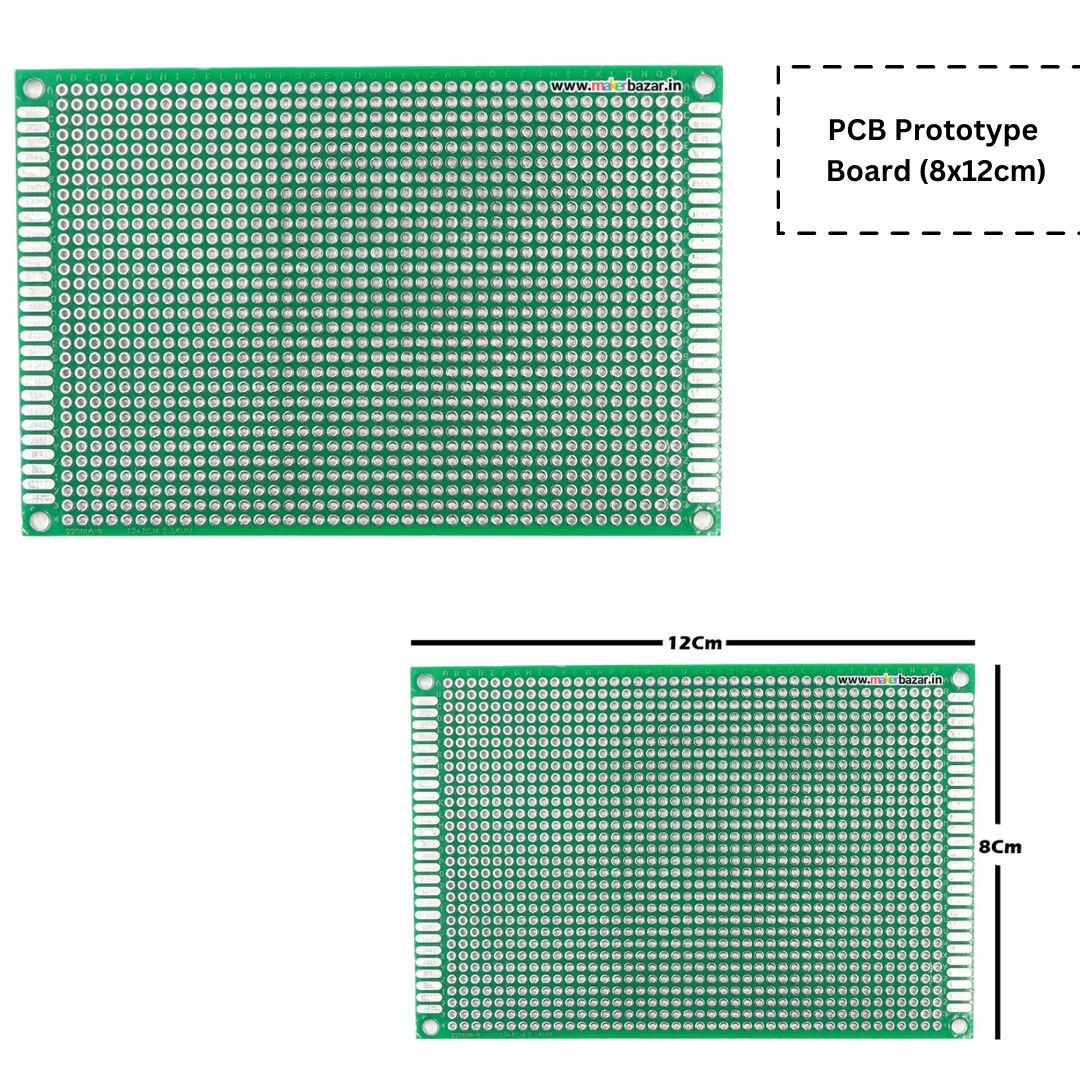

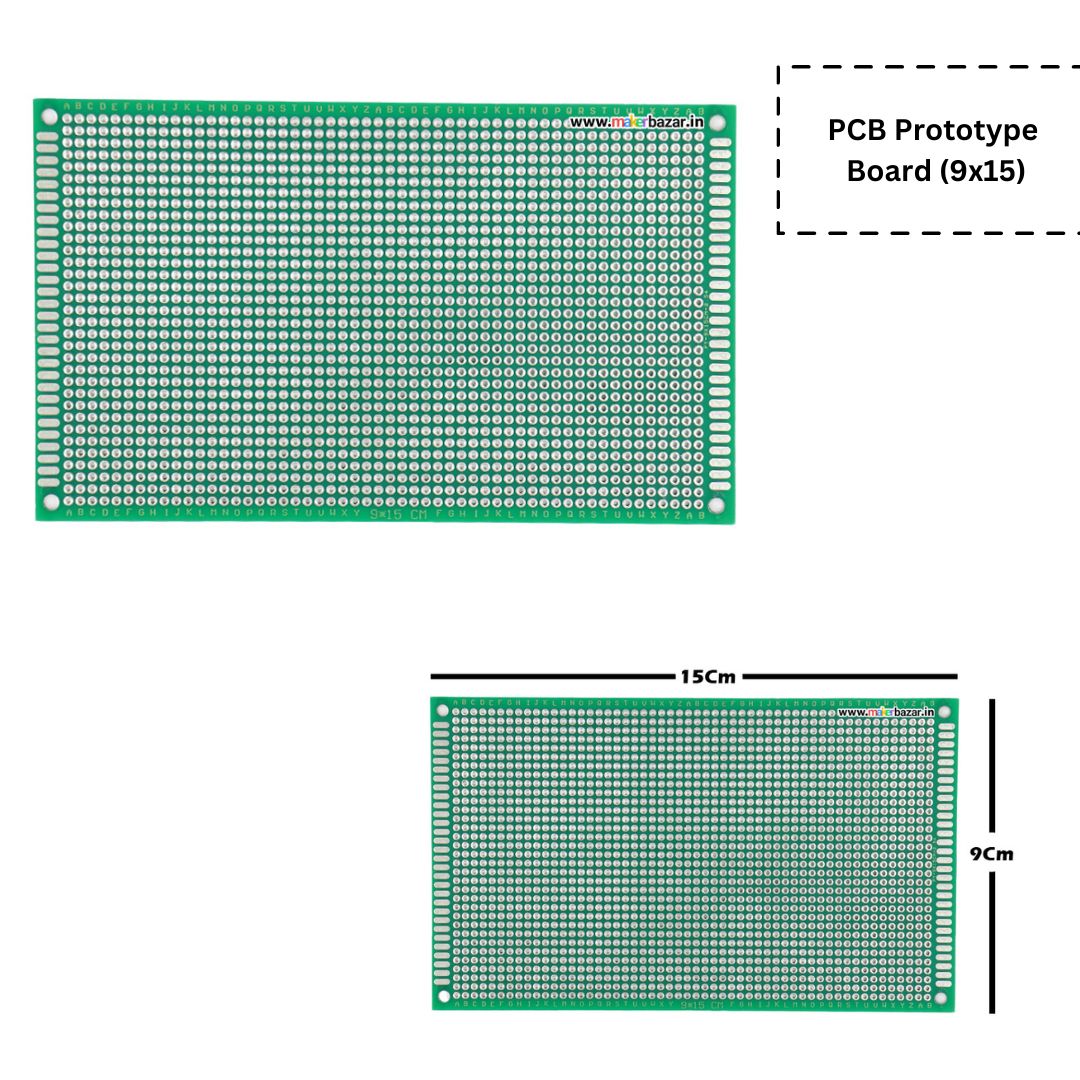

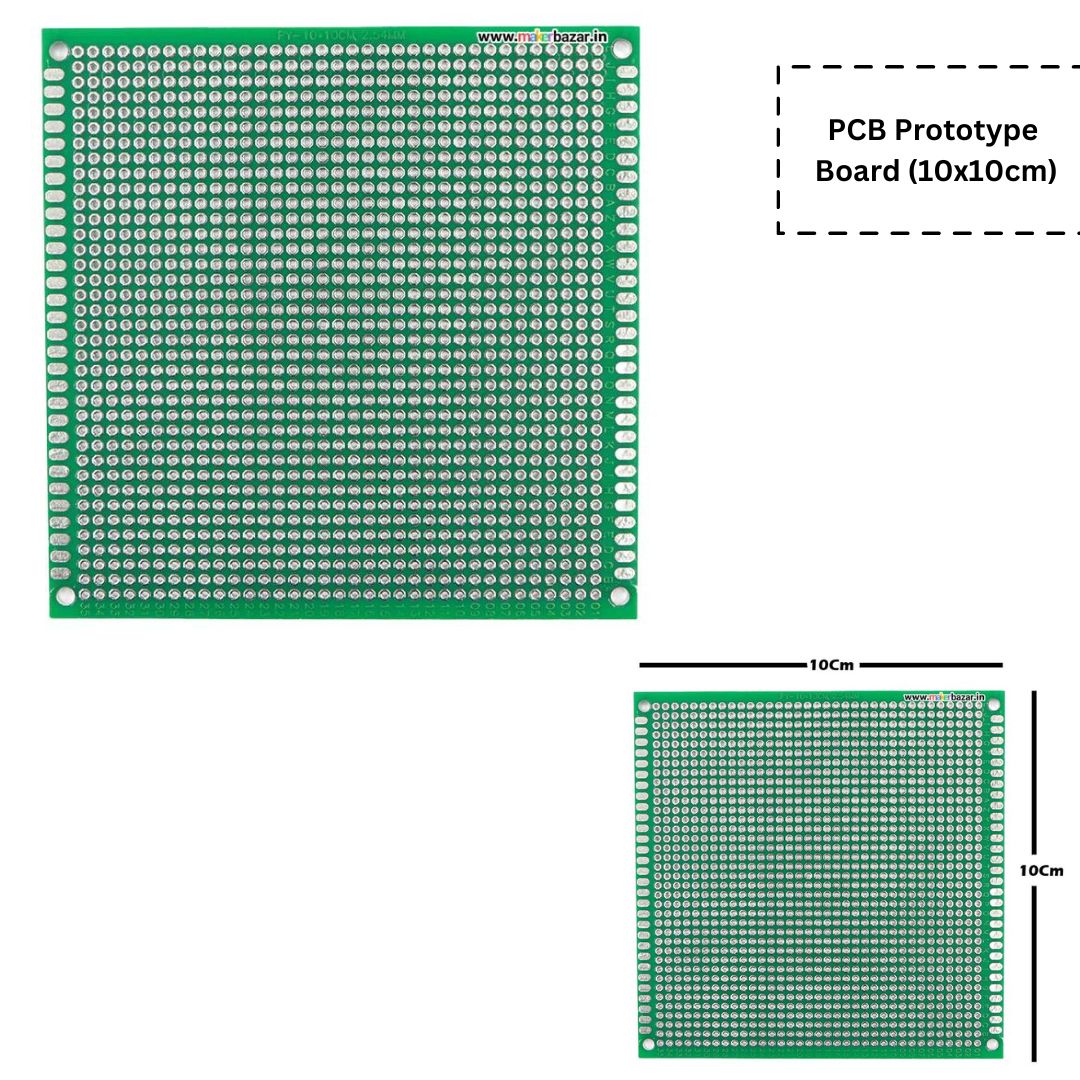

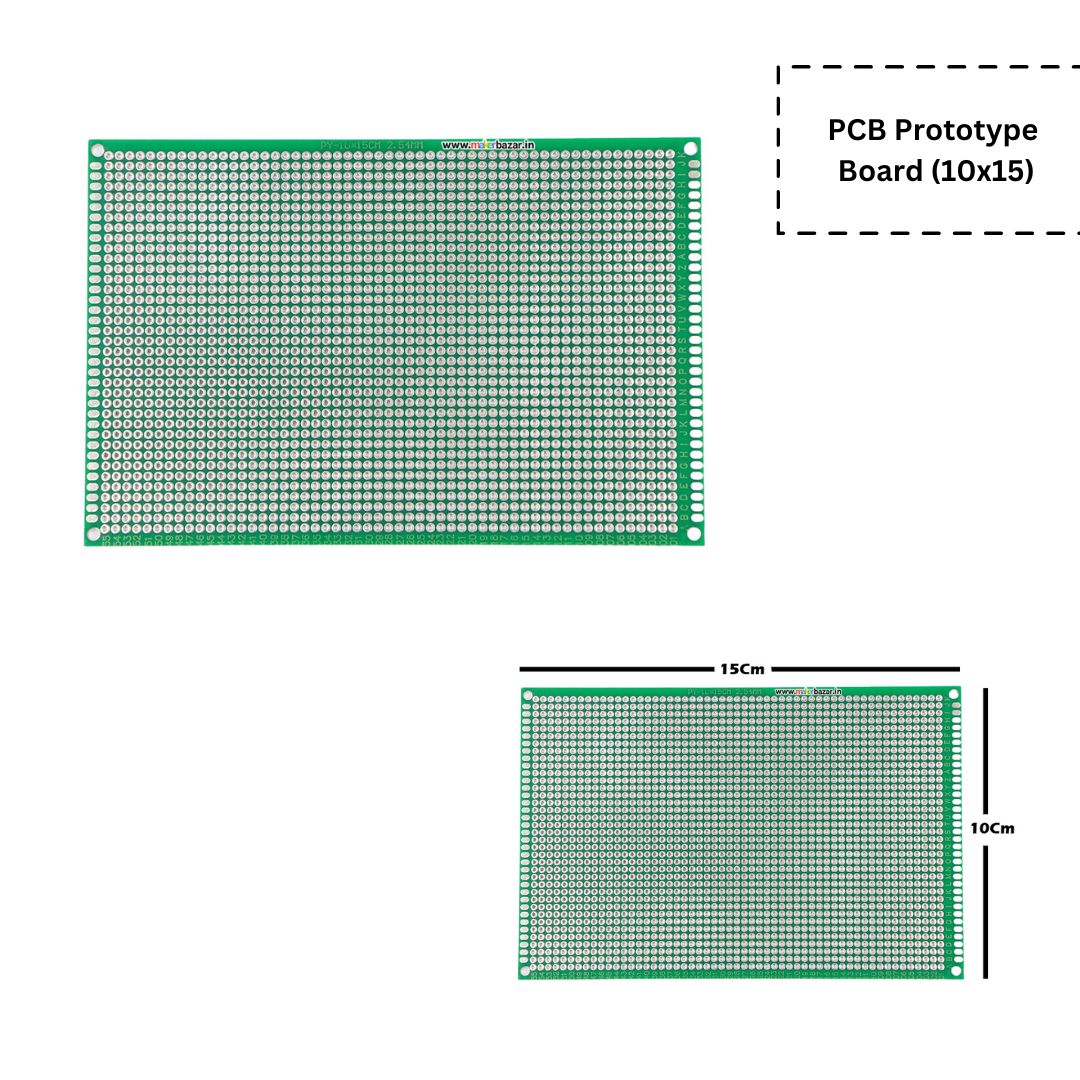

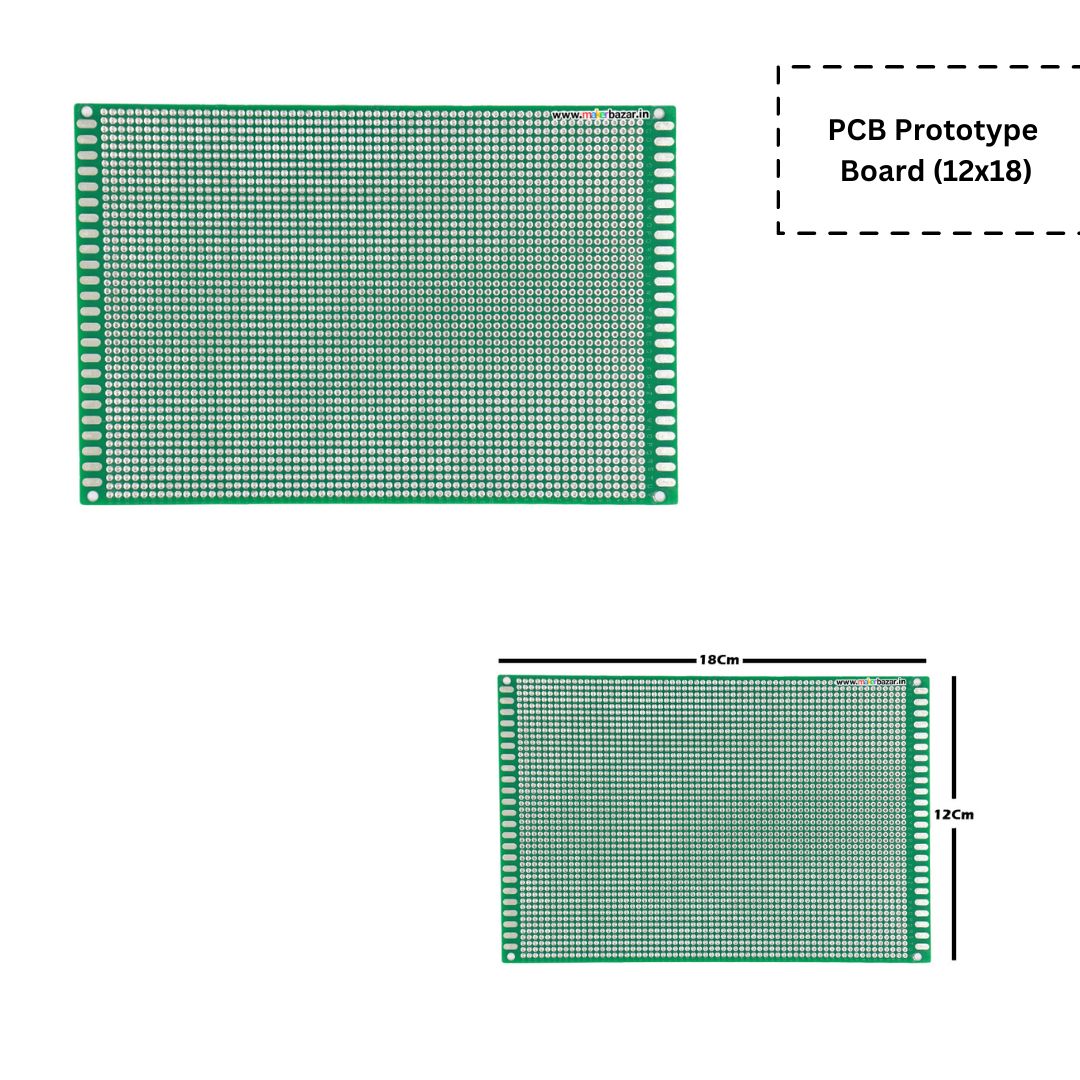

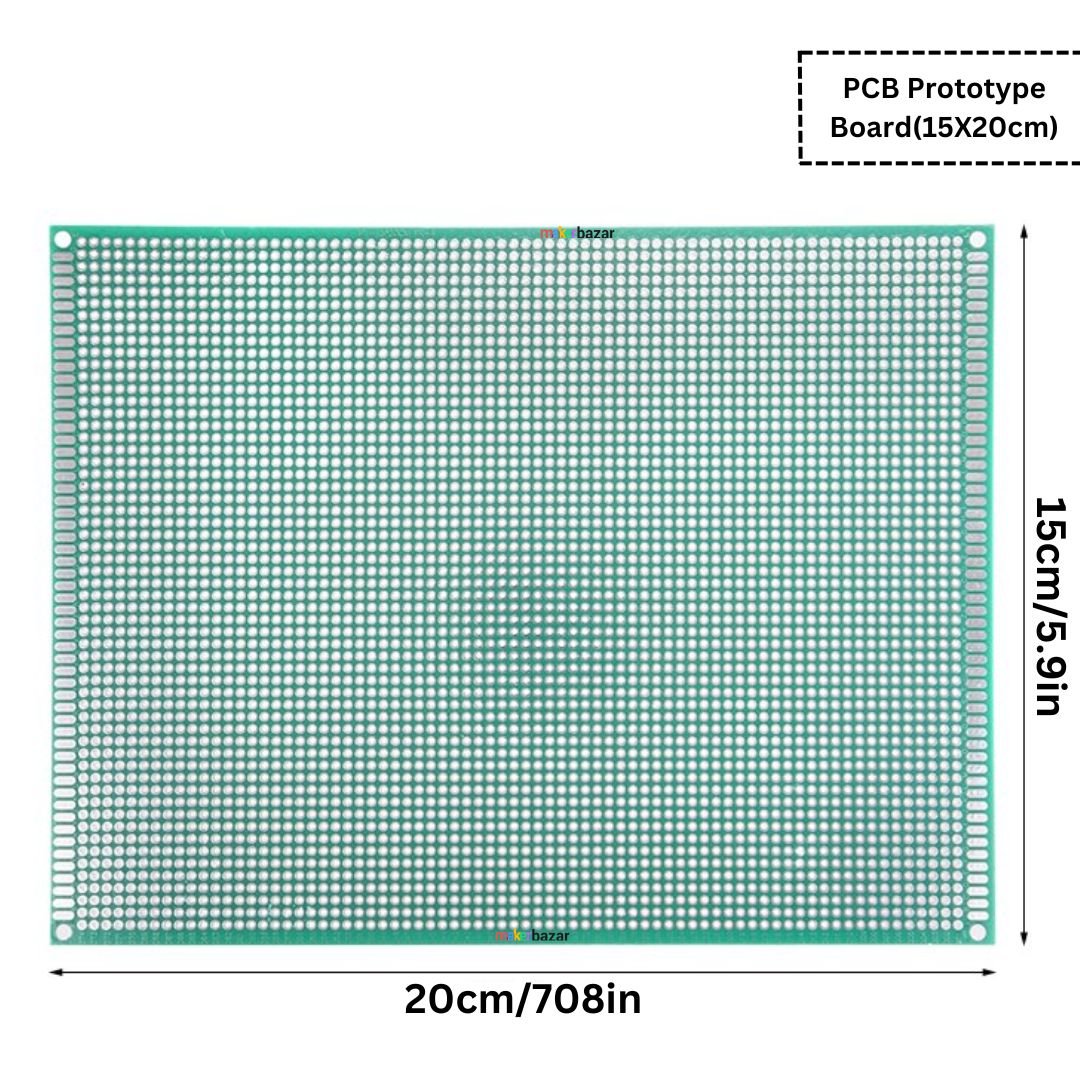

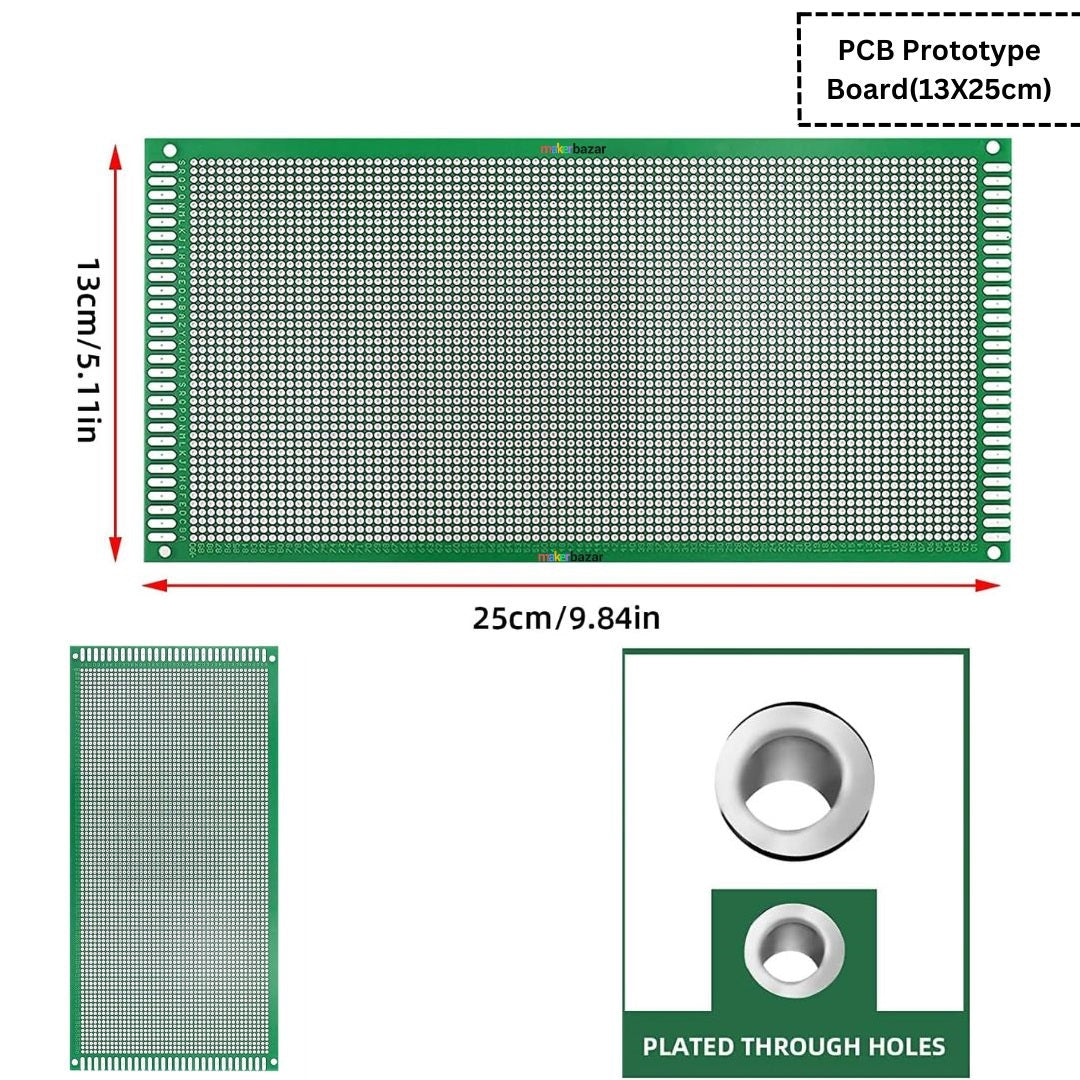

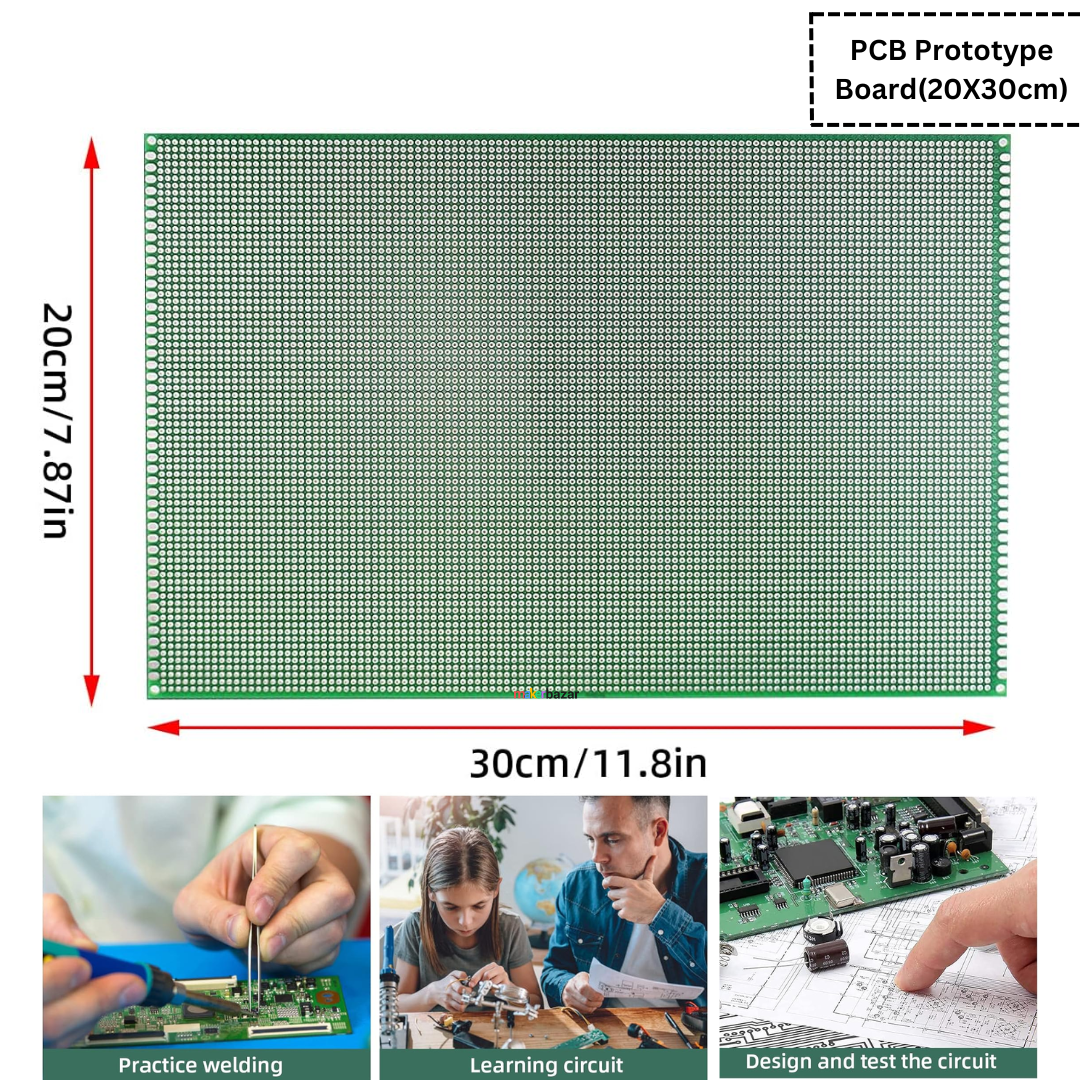

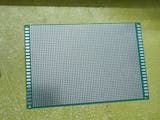

Prototype PCB Panel Universal Matrix Circuit Board for DIY Soldering- Green PCB/Zero Board

Universal PCB Prototype Board High-quality universal prototyping board with standard 0.1″ spacing through holes. High-quality FR4 material HASL, NC CNC drilled.

| Specification | Details |

|---|---|

| Base Material | FR4 |

| Copper Thickness | 1-4 OZ |

| Board Thickness | 1.6 mm |

| Minimum Hole Size | 0.3 mm |

| Minimum Line Width | 6 mil (0.1524 mm) |

| Minimum Line Spacing | 6 mil (0.1524 mm) |

| Surface Finishing | HASL |

Advantages:-

-

Increased Circuit Complexity: The biggest advantage is the ability to create a more complex circuit. With solderable surfaces, you have the real estate to place components and route circuit paths compared to a single-sided board. This allows you to build more intricate projects without needing to jump wires or resort to complex layouts on a single side.

-

Shorter Connections and Potentially Improved Performance: Since you can place components on both sides and route traces between them, you can potentially create shorter connections between components. Shorter connections generally mean lower resistance and capacitance, which can be beneficial for high-frequency circuits or those requiring precise signal integrity.

-

More Compact Designs: By effectively doubling your usable space, boards allow you to design more compact circuits. This can be important for projects with space limitations or for creating portable devices.

-

Standard Hole Pitch (2.54mm): The 2.54mm hole pitch is a standard spacing used in most electronic components with leads designed for breadboards and perfboards. This compatibility ensures a wide variety of components will fit easily into the board's holes for soldering.

-

Relatively Affordable: Prototype boards are generally more expensive than single-sided ones, but they are still a cost-effective way to develop and test circuits compared to fabricating custom PCBs.