Description

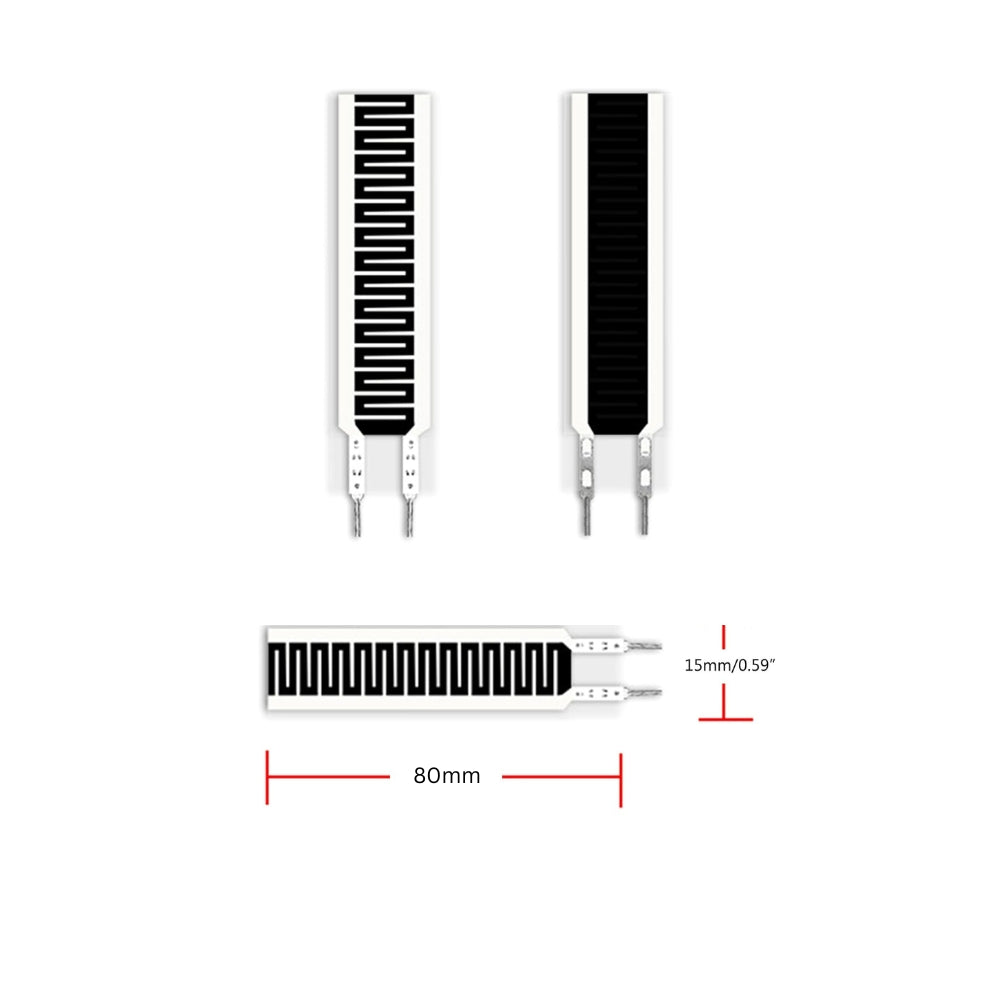

Flexible Piezoelectric Film Sensor – Pressure & Vibration Detection Module

The SF-15 is a thin, flexible, resistive-type pressure sensor designed to detect and measure force, load, or pressure through a change in electrical resistance. This sensor is ideal for applications where space-saving, lightweight, and flexible sensing elements are required. It responds predictably to increased pressure by decreasing its resistance, making it suitable for a variety of user interface, robotics, and industrial sensing applications.

Key Features:

-

Flexible and Ultra-Thin Design: Allows integration into compact or curved surfaces.

-

Force-Sensitive Resistor (FSR) Technology: Changes resistance with applied force.

-

Lightweight and Durable: Ideal for portable and embedded applications.

-

Fast Response Time: Suitable for real-time pressure monitoring.

-

Easy to Interface: Compatible with microcontrollers (Arduino, Raspberry Pi, etc.).

Technical Specifications:

| Parameter | Value |

|---|---|

| Model | SF-15 |

| Sensing Area | Ø 15 mm (Diameter) |

| Thickness | < 0.35 mm |

| Force Sensitivity Range | 0.1 N to 10 N (approx.) |

| Operating Voltage | 0 – 5 V DC (typical) |

| Resistance Range | >10 MΩ (no pressure) to ~1 kΩ (max) |

| Actuation Force | ~0.1 N (minimum detectable force) |

| Response Time | < 10 ms |

| Repeatability | ±2% of full scale |

| Operating Temperature | -20°C to +60°C |

| Connector Type | 2-pin solder pads or FPC terminals |

| Material | PET-based conductive polymer |

Working Principle:

When force is applied to the sensing area, the internal conductive particles of the sensor compress, causing a measurable decrease in electrical resistance. This resistance change can be measured via a simple voltage divider circuit.

Applications:

-

Pressure-sensitive touch interfaces

-

Robotics (grip force sensing)

-

Smart textiles and wearables

-

Industrial automation

-

Medical equipment (e.g., patient pressure pads)

-

Gaming and haptic feedback systems

Usage Tips:

-

Use with a pull-down resistor (typically 10kΩ) in a voltage divider configuration.

-

Calibrate for specific force ranges depending on the application.

-

Avoid sharp objects that could puncture the sensing film.